YA03 KIT AVIO

YAMAHA R1 2015 --->

CategoryAviofiber

Tissue946

ViewsTECHNOLOGY

FABRICS OF FILTERS

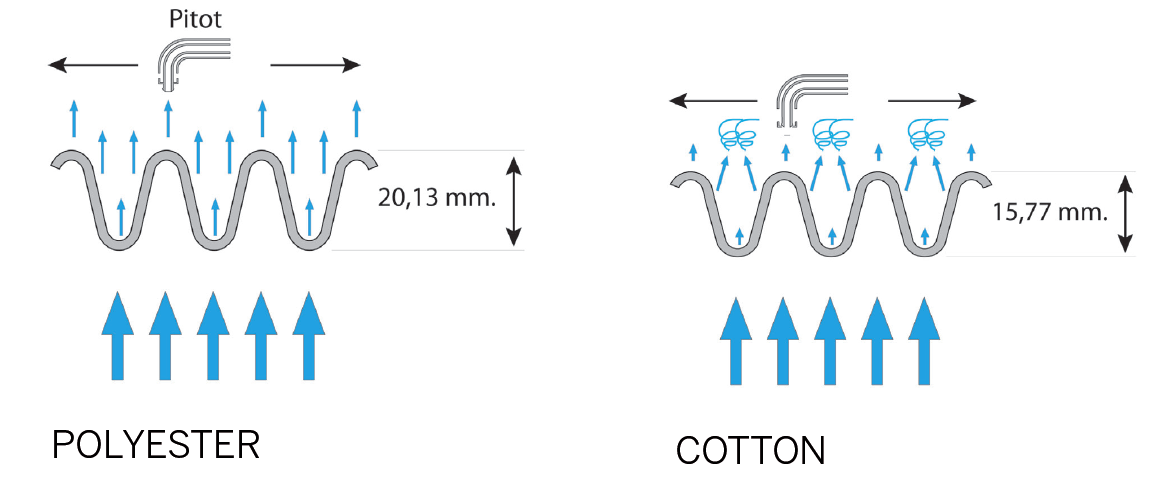

Current production vehicles are typically equipped with paper filters, while performance vehicles used oil-soaked cotton or sponge. An air filter job is to guarantee good air flow while preventing significant particles from ending up in the engine. These two operations naturally oppose each other and that is where Sprint Filters’ polyester filtering fabric takes a leap above the rest. Polyester fabric is extremely permeable, stable and is not affected by folding during construction. Cotton or sponge air filters, on the other hand, have a weaving that depends on the overlapping of numerous layers, leading to poor flow in some areas and ineffective filtration in others.

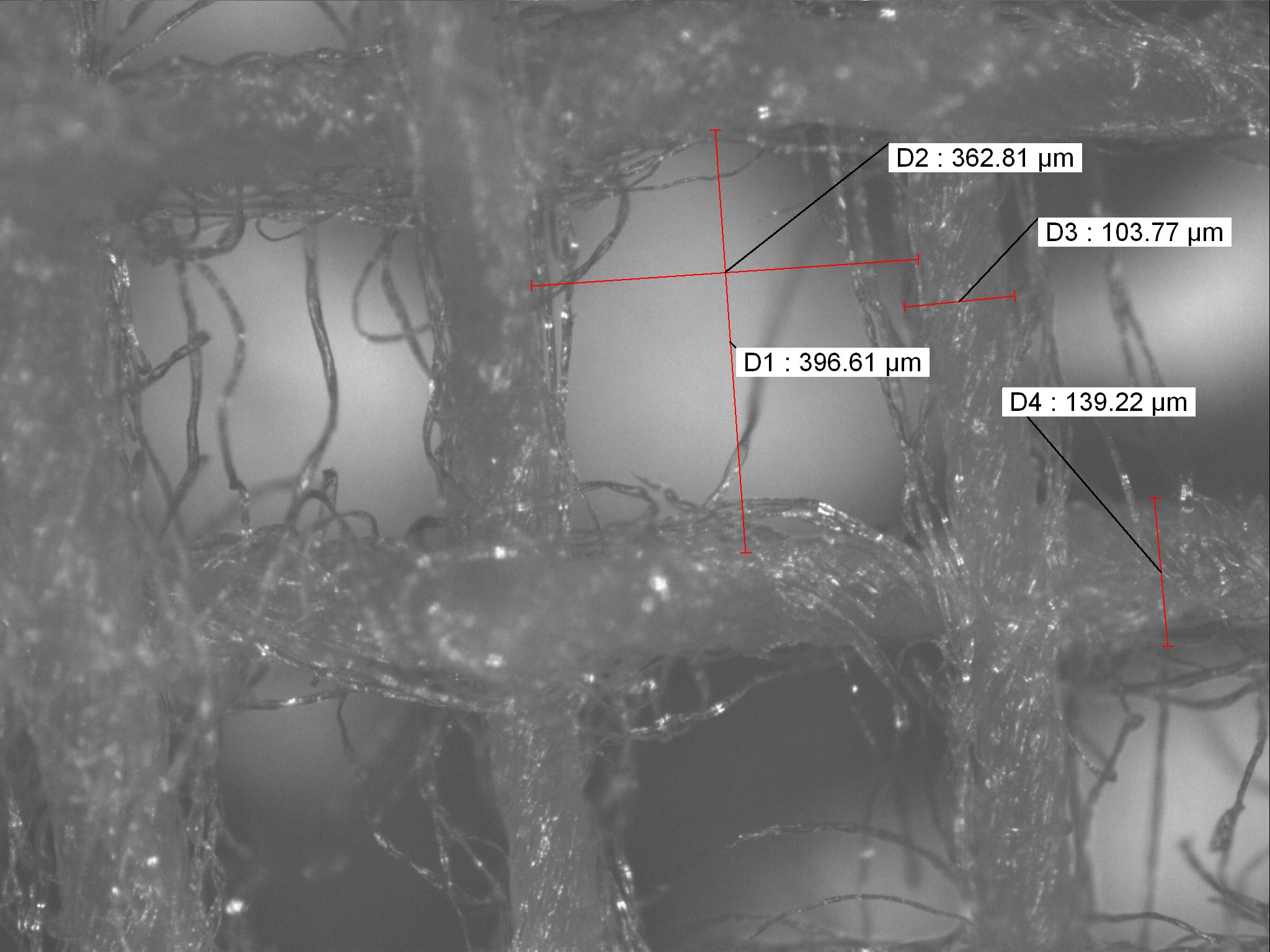

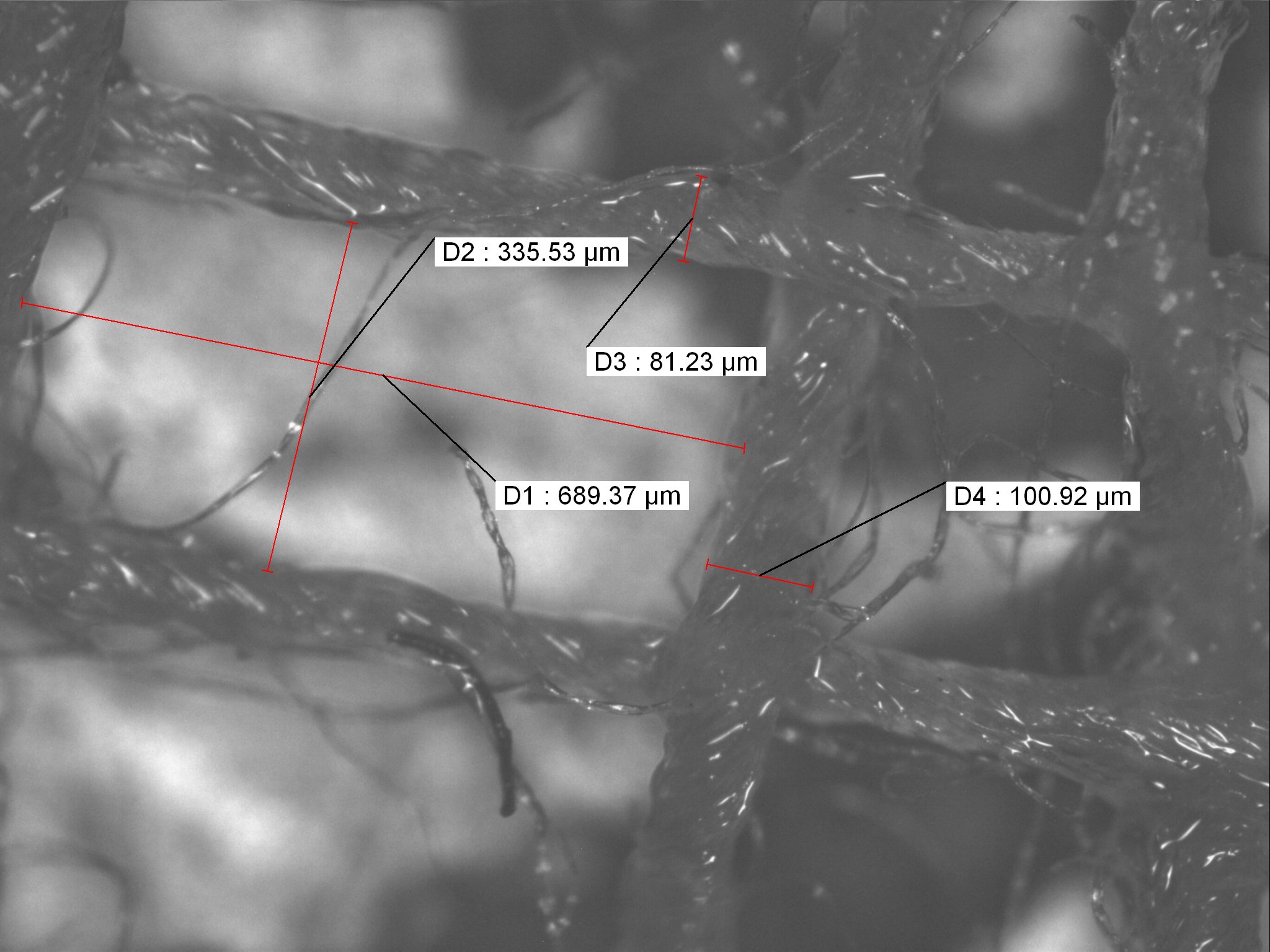

The construction precision of the Sprint Filter polyester air filters offers equal filtration that remains constant over time. By contrast, a cotton air filter has extremely variable openings, from just a few microns to several tenths.

Premium cotton 4 layers air filter - microscope view 10x

Premium cotton 4 layers air filter - microscope view 10x

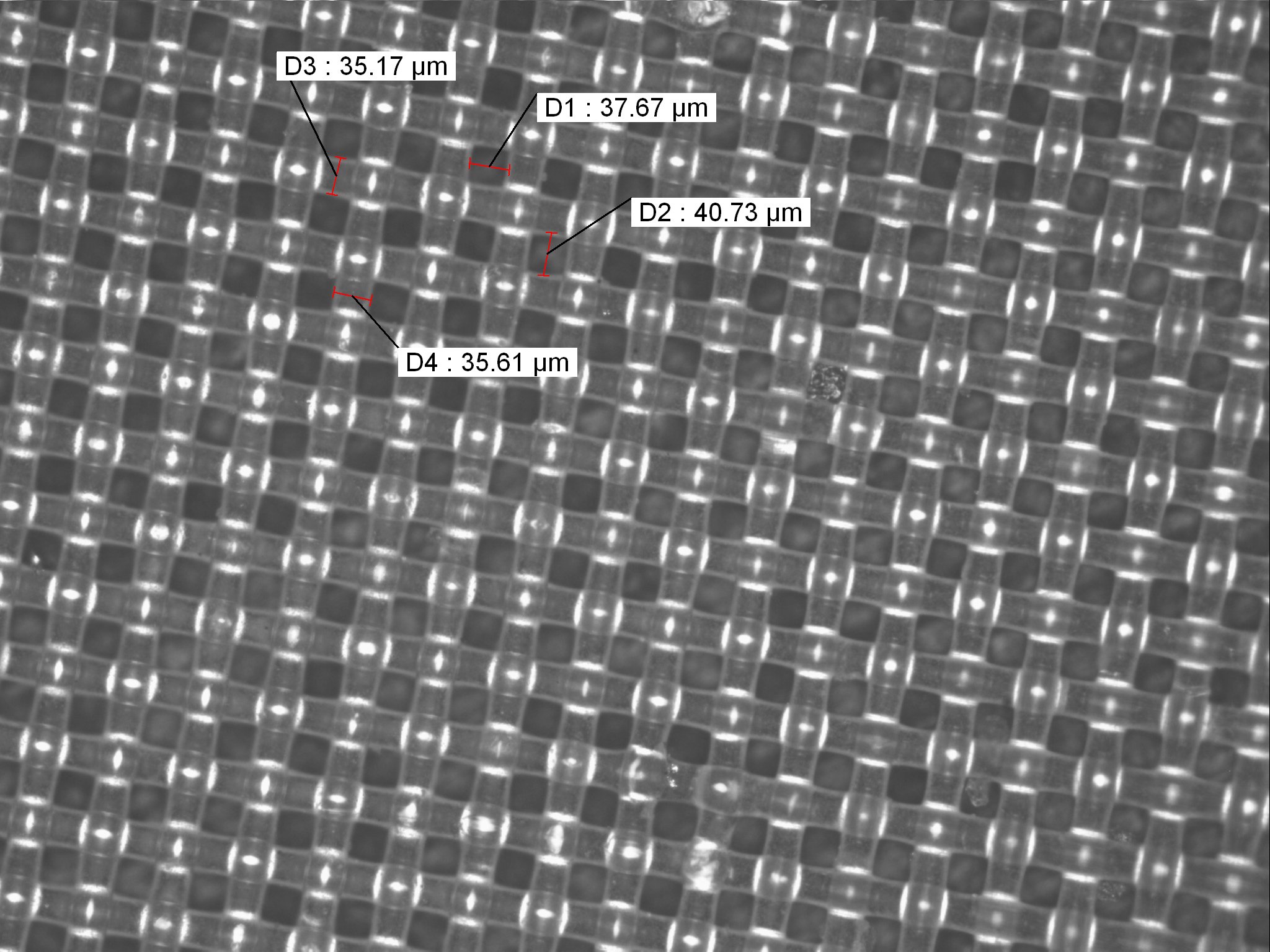

Sprint Filter P037 air filter microscope view 10x

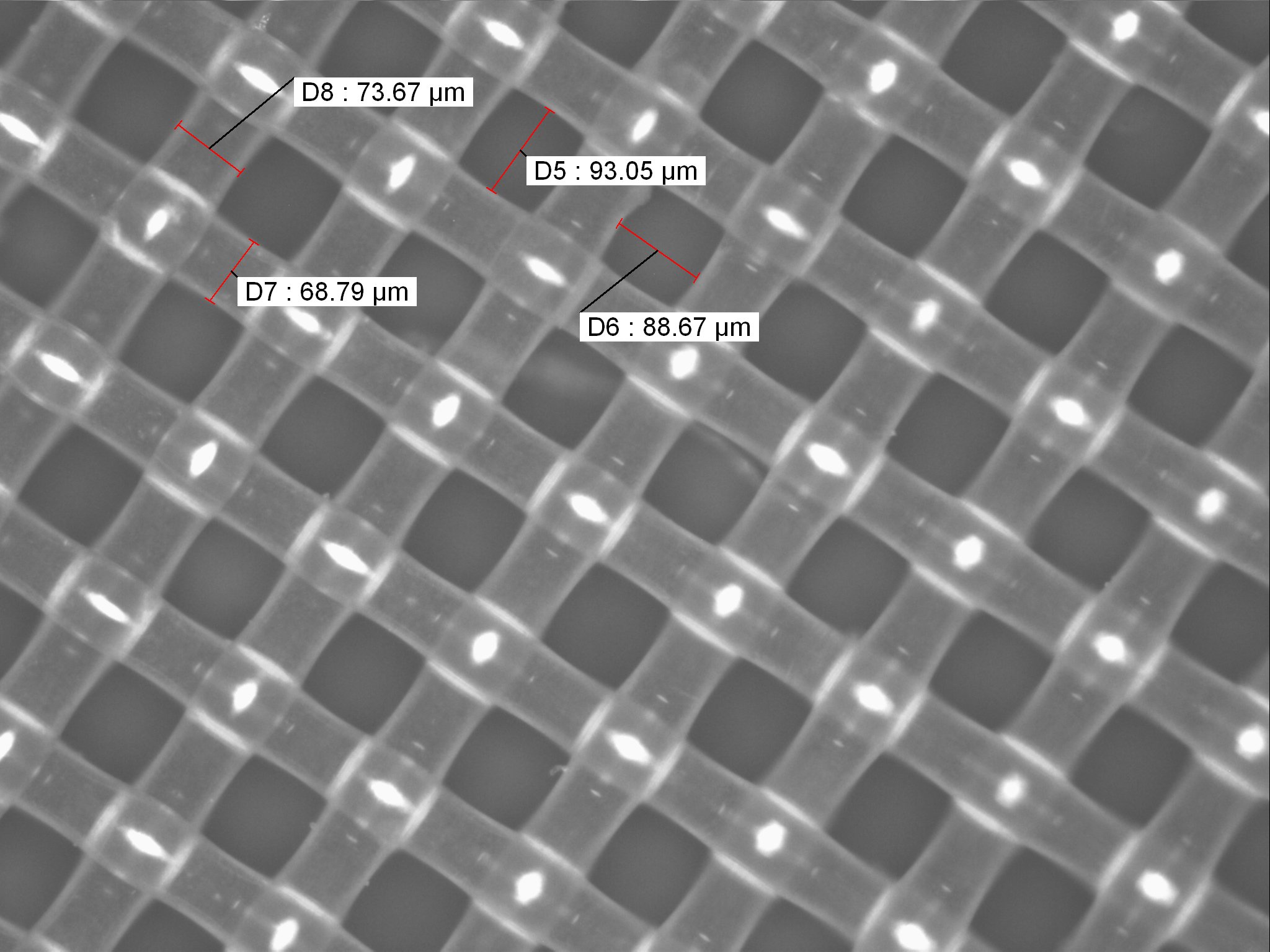

Sprint Filter P08 air filter microscope view 10x

AIRFLOW

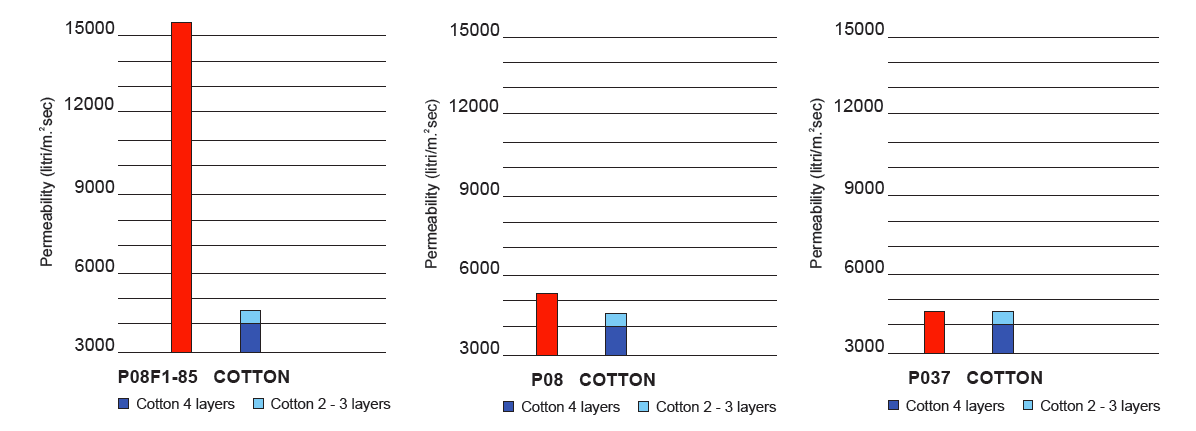

The uniform and compact polyester filtering element consists of a thin filament of fabric, forming a mesh of several dozen microns, capable of trapping all significant particles and ensuring a very high air flow rate. Our polyester air filter guarantees a very high air flow that neither cotton filters nor OEM paper filters can achieve. Remember this simple equation: More Air = More Power!

EFFICIENCY & FILTRATION

The Sprint Filter polyester air filters retain 93.13% of 100 μ particles (Sprint Filter P08 air filter) - 91.8% of 37 μ particles (Sprint Filter P037 air filter) - 95.22% of 100 μ particles (Sprint Filter P08F1-85 air filter) versus the 76.42% of 4-layer oil-soaked cotton

Because of its uniform structure, the Sprint Filter air filter ensures less air flow disturbance, also thanks to the exclusive and patented filtering material in single-layer polyester

THE REALIZATION

Sprint Filter creates over 50 years innovative products made with the most sophisticated and technologically advanced materials: from aluminum, steel, and then move on to materials in polyurethane foams and compact disks to get to plastics all kinds of fine carbon and kevlar. The entire process of manufacturing our products is done internally with sophisticated equipment design and production: designed with advanced three-dimensional cad-cam our filters and extraction systems are built using molds developed with numerical control machines and realizzatiinfine with modern machinery for molding plastics and dispensing of polyurethane.